Wond'ry Makerspace Hours

Mon-Thur, 1:00pm - 8:00pm

Fri, 1:00pm - 6:00pm

* Hours may periodically be variable due to special events, weather and student staffing schedules.

Looking to 3D Print or Laser Cut a part for a project? Use our new Wond'ry Makerspace Jobs Request Form to submit your files.

FAB Lab Team

-

Alexandra Sargent Capps

Fiber Arts Build Lab Manager

Available Equipment

Adaptive Clothing Resource Guide

Alicia Searcy, a treasured Wond'ry community partner and local Nashville fashionista born with cerebral palsy, dreamed of creating a guide for tailors that includes adaptive hardware and instructions for effectively altering clothes for people with disabilities in order to create a more equitable world. Two Wond'ry students in Professor Alex Sargent's Sustainable and Adaptive Fashion class, Trieu Vy Truong and Sophia Potter, began the work of building the guide by gathering research and interviewing a range of people. Soon, a collaborative team of community members and students pooled their talents to create this guide. Alicia's wishes include making the guide available to all by keeping it open source.

Please click the image below to download a copy of The Adaptive Clothing Resource Guide.

Mix Your Makerspaces!

The Wond'ry's Makerspaces are co-located to optimize interdisciplinary prototyping. Read below for ideas on how to mix different makerspace specialties for innovative creations. All the examples below are real ideas that have come through the Wond'ry!

Curricular Classes

In the News

-

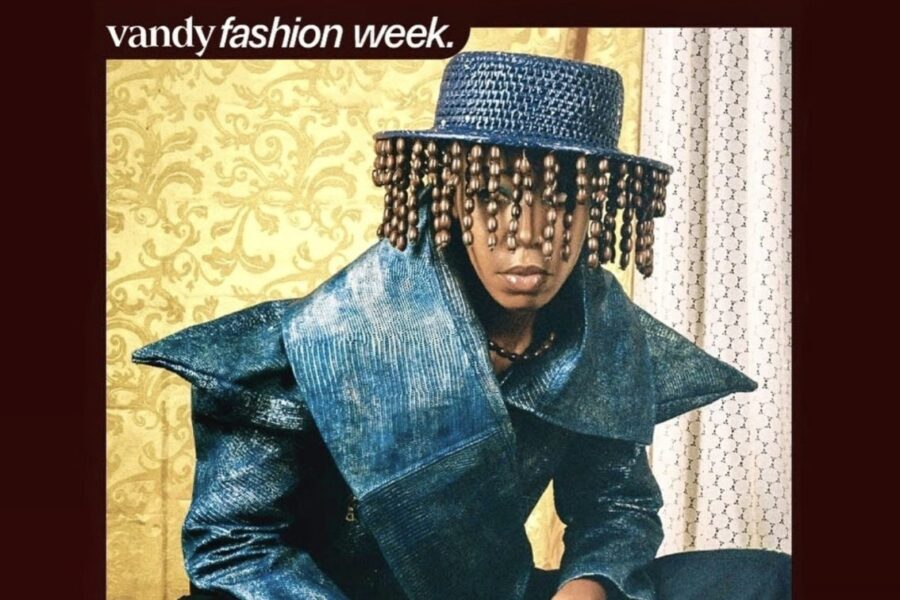

Sustainable style: Celebrating the third year of Vanderbilt Fashion Week

It’s in this spirit of exploration and discovery that Vanderbilt Fashion Week (VFW) stands out, speaking directly to the Vanderbilt community with a ... -

Crafting a sustainable style: Exploring the Wond’ry Fiber Arts Lab’s fashion innovations

From a professor’s corner desk with a singular sewing machine to an entire Makerspace equipped with eight industrial sewing machines, design spaces an ... -

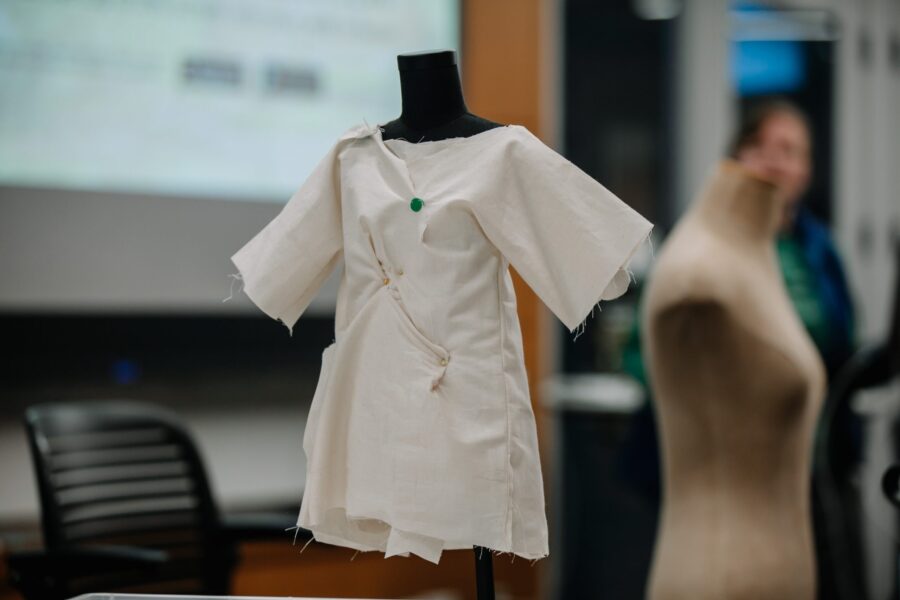

Wond’ry Fiber Arts Build Lab hosts interdisciplinary sprint to design dignity-centered hospital gowns

In a crossover between science and art, students, staff and faculty from Vanderbilt, other universities and Vanderbilt University Medical Center worke ...

External Resources

- Ellen Macarthur Foundation: Circular Business Models – Discover examples of companies implementing circular business models in the fashion industry with this selection of case studies from around the world.

- Vanderbilt Fashion Week - VFW connects trailblazing companies and up-and-coming designers from around the world with students from across Vanderbilt's campus and the Greater Nashville area in order to create an inventive and inspiring sustainable fashion ecosystem that maximizes prosperity, idea sharing, and positive value change.

Needles, thread, pins, scissors, thread rippers, measuring tools, grommeters, awls, edge tools, and just about everything needed to sew by hand.

Needles, thread, pins, scissors, thread rippers, measuring tools, grommeters, awls, edge tools, and just about everything needed to sew by hand. For heavy-duty textiles that would break the average sewing machine, we have an industrial sewer that can handle tougher fabrics such as sailcloth, kevlar, and leathers.

For heavy-duty textiles that would break the average sewing machine, we have an industrial sewer that can handle tougher fabrics such as sailcloth, kevlar, and leathers. A longer arm than the average machine allows for sewing large-scale pieces like blankets, banners, tarpaulins, tubes, and sleeves.

A longer arm than the average machine allows for sewing large-scale pieces like blankets, banners, tarpaulins, tubes, and sleeves. Sergers create finished edges to textiles, preventing unraveling or damage as a fabric is used.

Sergers create finished edges to textiles, preventing unraveling or damage as a fabric is used. Allows the transference of digital assets (such as raster or vector images or text) onto textiles.

Allows the transference of digital assets (such as raster or vector images or text) onto textiles. Allows for the creation of custom woven textiles from a variety of materials.

Allows for the creation of custom woven textiles from a variety of materials. Available in both male and female options, these forms are one-half the average human scale. The smaller size allows for the rapid creation of prototypes, more quickly and using less materials than a full-scale model.

Available in both male and female options, these forms are one-half the average human scale. The smaller size allows for the rapid creation of prototypes, more quickly and using less materials than a full-scale model. Available in both male and female options and a variety of sizes, full-scale dress forms allow for the creation of functional, wearable prototypes.

Available in both male and female options and a variety of sizes, full-scale dress forms allow for the creation of functional, wearable prototypes. Beyond presentational neatness, using an iron to smooth textiles make them easier to perform machine work upon.

Beyond presentational neatness, using an iron to smooth textiles make them easier to perform machine work upon.