Recent News

Our structural health monitoring (SHM) research is developing techniques for:

- Detection, localization, and quantification of structural damage (damage diagnosis)

- Forecasting future damage growth and estimation of the remaining useful life of the structure (prognosis)

- Uncertainty quantification in damage diagnosis

- Uncertainty propagation to perform probabilistic system prognosis.

Funding

Current People

- Sankaran Mahadevan, Professor

- Douglas Adams, Professor

- Pranav Karve, Assistant Research Professor

- Yanqing Bao, Postdoctoral Research Scholar

- Sarah Miele, Ph.D. Student

- Yulin Guo, Ph.D. Student

- Gbandi Nikabou, Ph.D. Student

- Christopher Nash

- Julia Finfrock, Undergraduate Researcher

- David Koester, Research Engineer

- Garrett Thorne, Staff Engineer

Publications

1. Bao, Y., & Mahadevan, S. (2015). Uncertainty quantification of thermal image-based concrete diagnosis. International Journal of Sustainable Materials and Structural Systems, 2(1-2), 77-95.

2. Bao, Y., & Mahadevan, S. (2019). Harmonic vibration testing for damage detection and localization in concrete. Structural Health Monitoring, 18(5-6), 1820-1835.

3. Karve, P., & Mahadevan, S. (2020). On the performance of vibro‐acoustic‐ modulation‐based diagnosis of breathing cracks in thick, elastic slabs. Structural Control and Health Monitoring, 27(3), e2470.

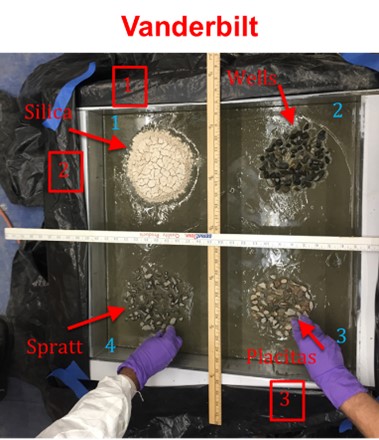

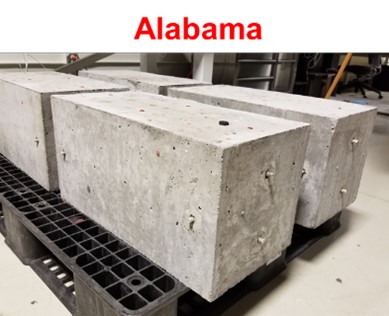

4. Karve, P., Miele, S., Neal, K., Mahadevan, S., Agarwal, V., Giannini, E. R., & Kyslinger, P. (2020). Vibro-acoustic modulation and data fusion for localizing alkali–silica reaction–induced damage in concrete. Structural Health Monitoring, 1475921720905509.

5. Karve, P. M., Guo, Y., Kapusuzoglu, B., Mahadevan, S., & Haile, M. A. (2020). Digital twin approach for damage-tolerant mission planning under uncertainty. Engineering Fracture Mechanics, 225, 106766.

6. Nash, C., Karve, P., Adams, D., Mahadevan, S., & Thorne, G. (2020). Real-time cure monitoring of fiber-reinforced polymer composites using infrared thermography and recursive Bayesian filtering. Composites Part B: Engineering, 198, 108241.

Concrete Structural Health Monitoring

Concrete Structural Health Monitoring

Higher cost and longer manufacturing lead times associated with FRP composites hinder their utilization in high-volume industries (wind, consumer automotive, and compressed gas storage). Real-time monitoring of the curing process can be crucial for adaptive decision-making to reduce cycle time, energy usage, and timely potential flaw identification and repair.

Higher cost and longer manufacturing lead times associated with FRP composites hinder their utilization in high-volume industries (wind, consumer automotive, and compressed gas storage). Real-time monitoring of the curing process can be crucial for adaptive decision-making to reduce cycle time, energy usage, and timely potential flaw identification and repair.