Physics Demo Number: 127 |

Approximate Run Time: 15 min |

|||||||

|

Diffraction From The Steel Rulings on a Machinist's Ruler aka: Measure the Speed of Light with A Ruler |

||||||||

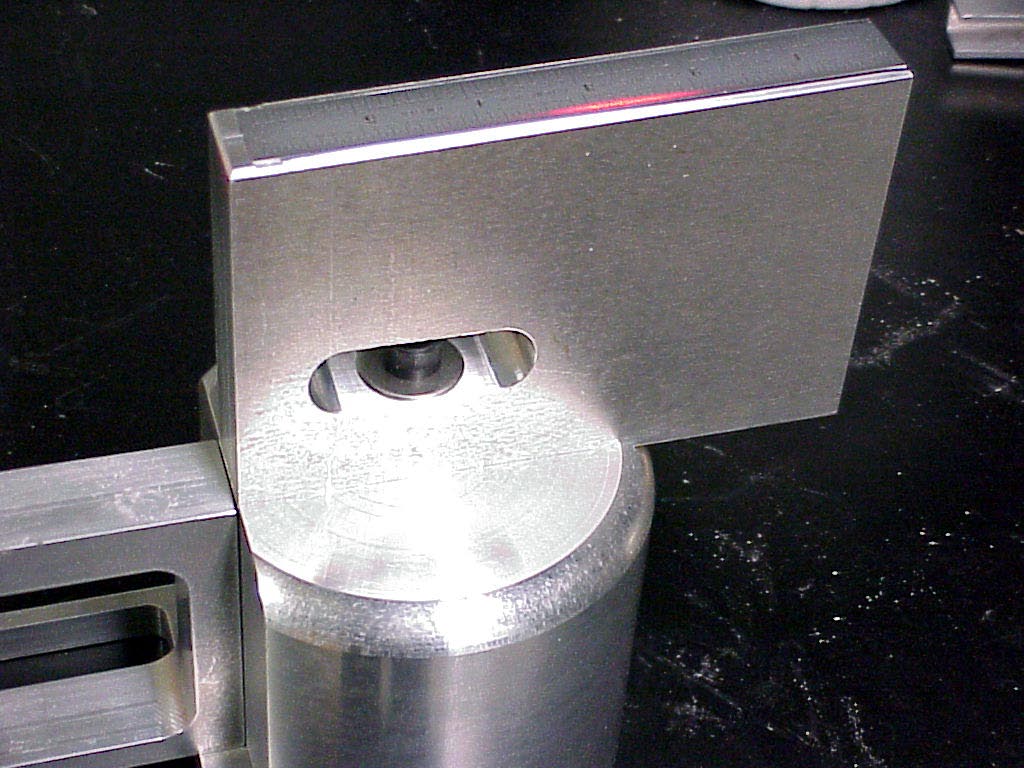

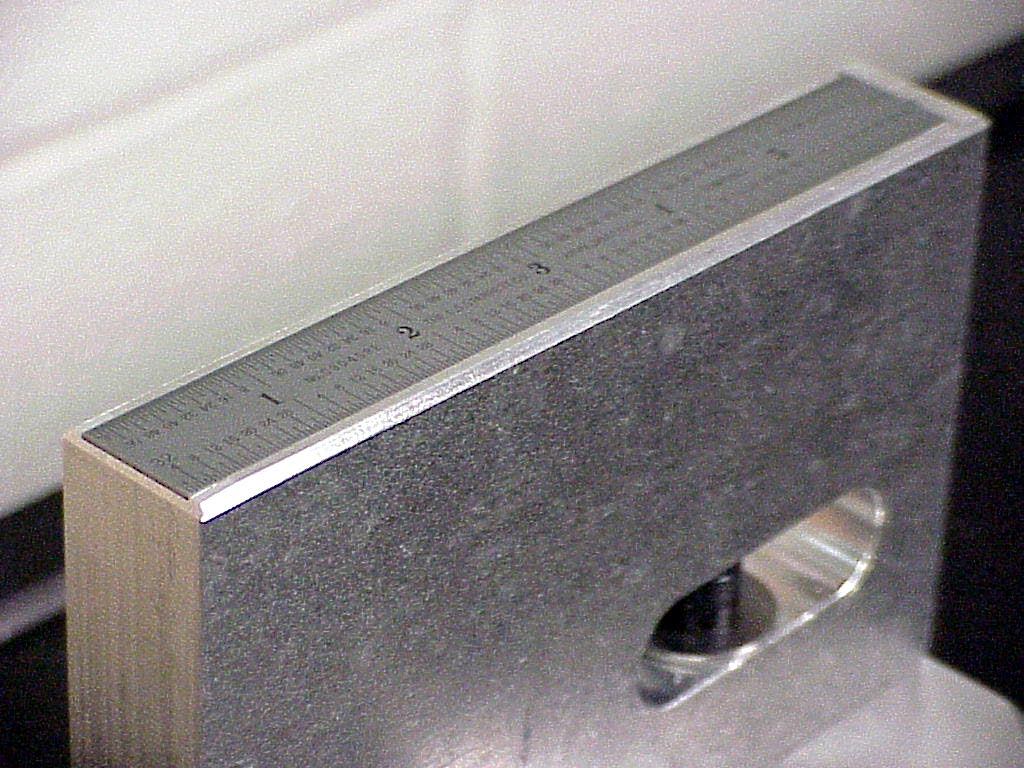

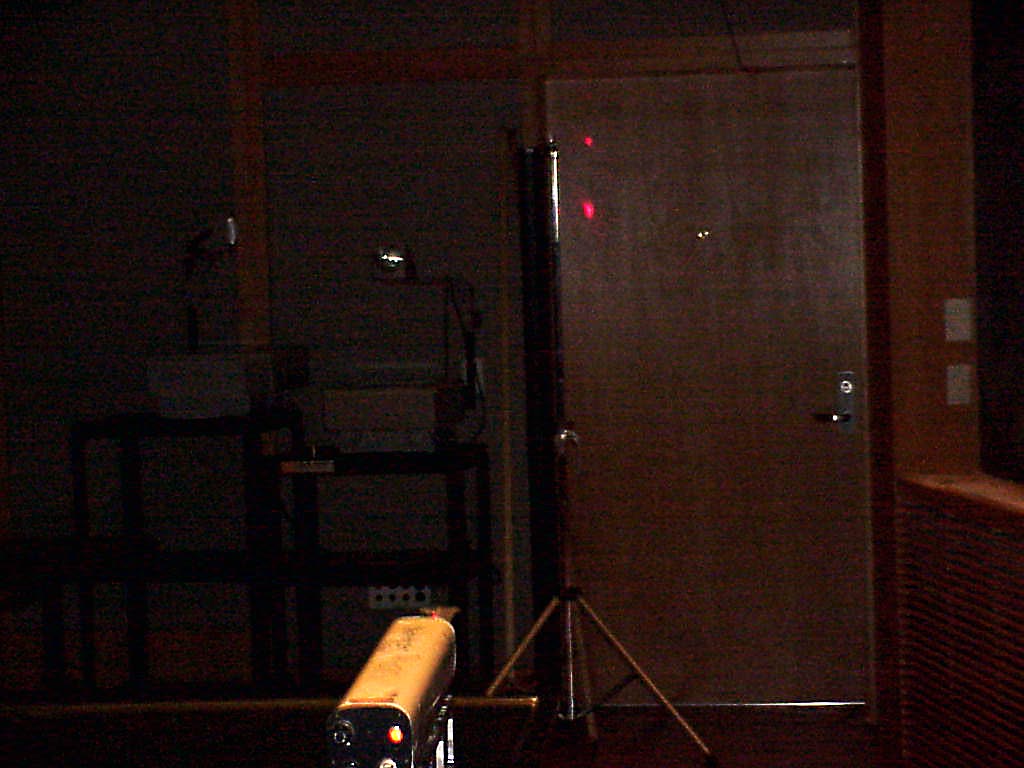

Demo DescriptionA dedicated fixture for holding a 6 inch Machinist's rule precisely aligned with a laser allows one to reflect the beam off the rule and observe the diffraction spots from the rule's markings on the wall. One can then determine the wavelength of the light quite accurately from direct measurements of the distances involved. |

|

Scientific Principles

|

||||||

Equipment

|

|

Equipment Location

|

||||||

1

|

2

|

|||||||

3

|

4

|

|||||||

|

|

||||||||